Galvanizing Job Work

Engineering. Fabrication. Galvanizing.

Hot dip galvanizing stands as a crucial process, immersing steel or iron into molten zinc to forge a shield against corrosion. By undergoing this method, the metal gains a resilient coat, offering formidable defense against rust and degradation, particularly suited for outdoor settings.

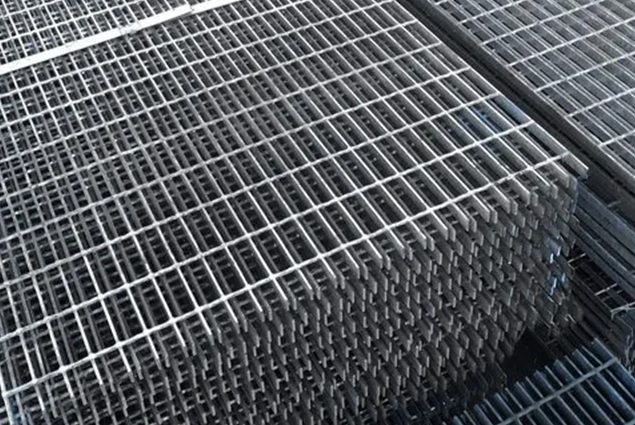

The process unfolds with meticulous cleaning of the metal surface, followed by immersion into a pool of molten zinc, and culminates in a cooling phase. This meticulous sequence yields a metallurgically bonded layer, ensuring enduring safeguarding for the underlying metal. Widely adopted across sectors like construction, automotive, and infrastructure, hot dip galvanizing finds versatile applications encompassing structural steel, outdoor fixtures, and highway guardrails.

Enhance the resilience and lifespan of your metal wares with our premium hot dip galvanizing services. As a forefront provider in the field, we specialize in shielding steel and iron surfaces from corrosion and rust, ensuring their endurance even in rigorous conditions.

Our cutting-edge facilities and seasoned team guarantee top-tier outcomes, delivering a consistent and enduring zinc coating through the hot dip galvanizing technique. From structural steel to industrial components, our services accommodate a diverse array of applications spanning across industries such as construction, automotive, infrastructure, and beyond.

We offer a comprehensive range of products, including Hot Dip Galvanizing Services, Hot Dip Pipe Galvanizing Services, Galvanized Iron Hot Dip Galvanising Service, and more.

Further Details:

- Production Capacity: 2500 Metric Tons per Month

- Delivery Time: 1 Day

- Packaging Details: Securely Strapped

Our partners

Well-known international companies